To live, we must daily break the body and shed the blood of Creation. When we do this knowingly, lovingly, skillfully, reverently, it is a sacrament. When we do it ignorantly, greedily, clumsily, destructively, it is a desecration. In such desecration we condemn ourselves to spiritual and moral loneliness, and others to want.

Wendell Berry, Art of the Commonplace: The Agrarian Essays

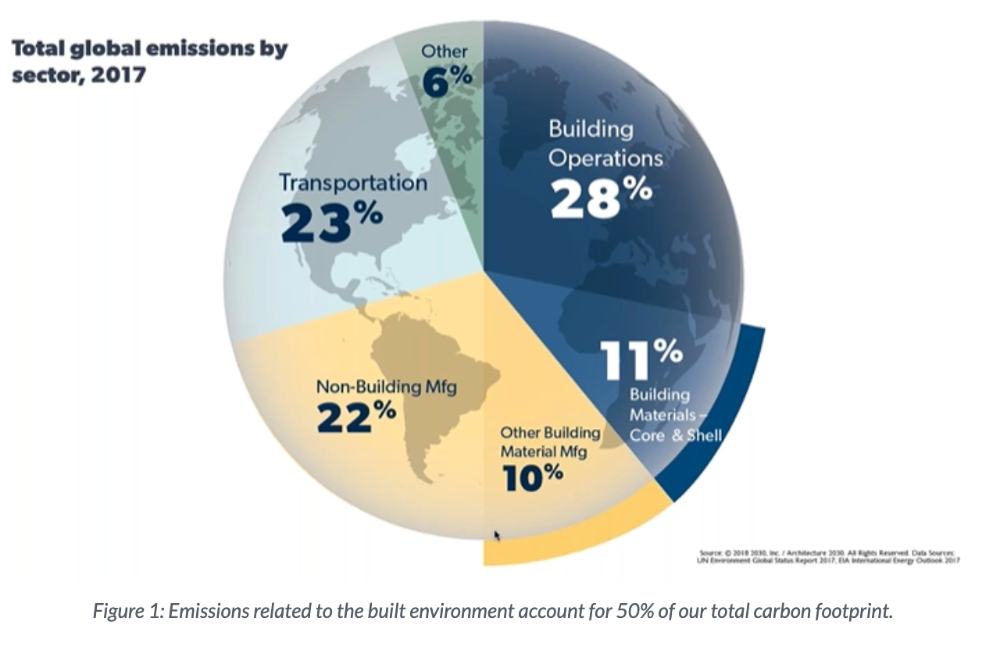

How we design and build homes matters. Buildings generate nearly 40% of annual global greenhouse gas emissions. Like other human enterprises, we “break the body and shed the blood” of our Planetary Mother as we build and live in what we build. There are environmental costs to all human activity, right? But maybe, when we construct with knowledge, love, skill and reverence, homebuilding can be holy work. We can access the most current knowledge of the way the world works, the science of climate and indigenous wisdom passed down for generations. We can build out of love for all our neighbors in the great web of life, knowing that the consequences of global heating harm marginalized human communities and endangered species first and most. We can employ the skill to find better and better ways to cooperate with nature in structures that harm less and regenerate more. We can revere those eternal forces, in and among us, (whatever we choose to call them) that ultimately determine whether we thrive together or end up in Dante’s Great Fiery Dumpster.

The late theologian Sallie McFague, author of A New Climate for Theology: God, the World and Global Warming (Fortress Press: 2008), posited three House Rules for those who would be good housemates in our own houses and the House of Earth:

- Take only your share.

- Clean up after yourselves.

- Keep the house in good repair for future occupants.

All this to say, when we decided to build, we wanted to honor the Rules of the House. After all, it’s really about loving neighbors and doing to others as we would have them do to us. We set out to meet the highest possible standard of neighborliness with our current housemates and those who will move in after us. We want to be held to account for the long-term impact of what we create. So we chose the building standard set by Passive House Institute of the United States (PHIUS).

You may not know anything of Passive House certification. You likely have heard of the LEED or Energy Star standards for buildings. Earth Advantage (www.earthadvantage.org) certification is also becoming more common. The conversations that led to Passive House standards began in the U.S. in the early 1970s, when the OPEC oil embargo led to artificially high prices for fossil energy. Those conversations died down in our country as soon as the price of gasoline at the pump dropped back again. But the sense of urgency was more sustained in Europe. So Passivhaus as a building standard was born in Germany and is well on it’s way to becoming a national requirement for all new buildings there. It has now returned here with the PHIUS program more appropriate for American building.

Why is this important in a climate emergency? Well, in Oregon, buildings are second only to transportation among the largest sources of greenhouse gas emissions. Building emissions come predominantly from burning methane gas and other fossil fuels. Globally, buildings generate 39% of annual emissions. Building operations (what it takes to live in the building) are responsible for 28% while building materials and construction (embodied carbon) generate 11%. Passive House standards target that 28% of annual emissions generated by how we run the house. You can see how energy efficient homes are in that first line of defense from climate harms. The key to mitigating climate emissions and protecting communities from climate-fueled wildfires, smoke and extreme temperatures is to build more energy efficient, climate-friendly buildings.

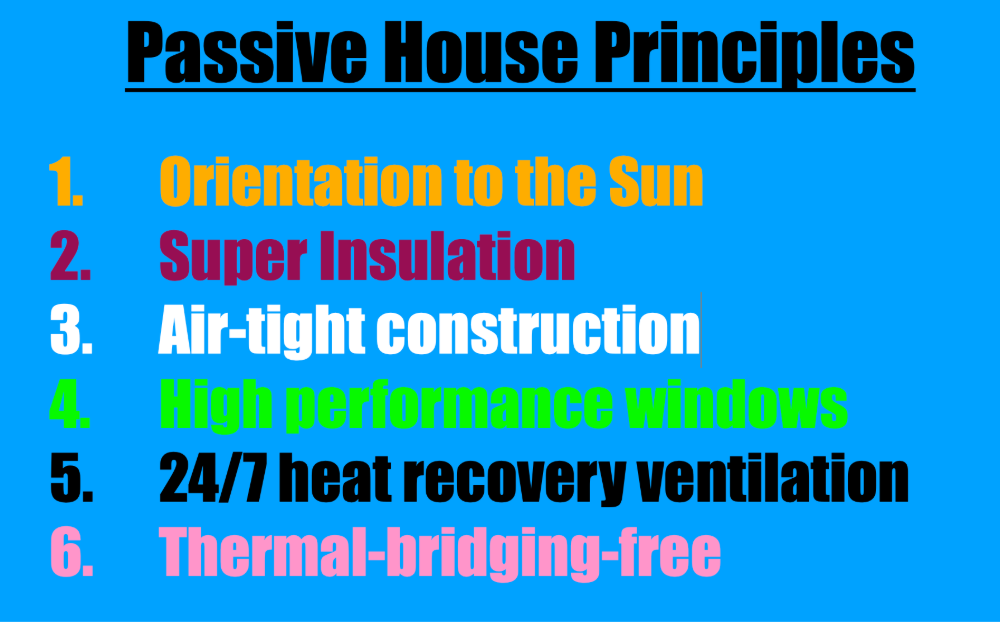

So what are the principles of Passive House construction?

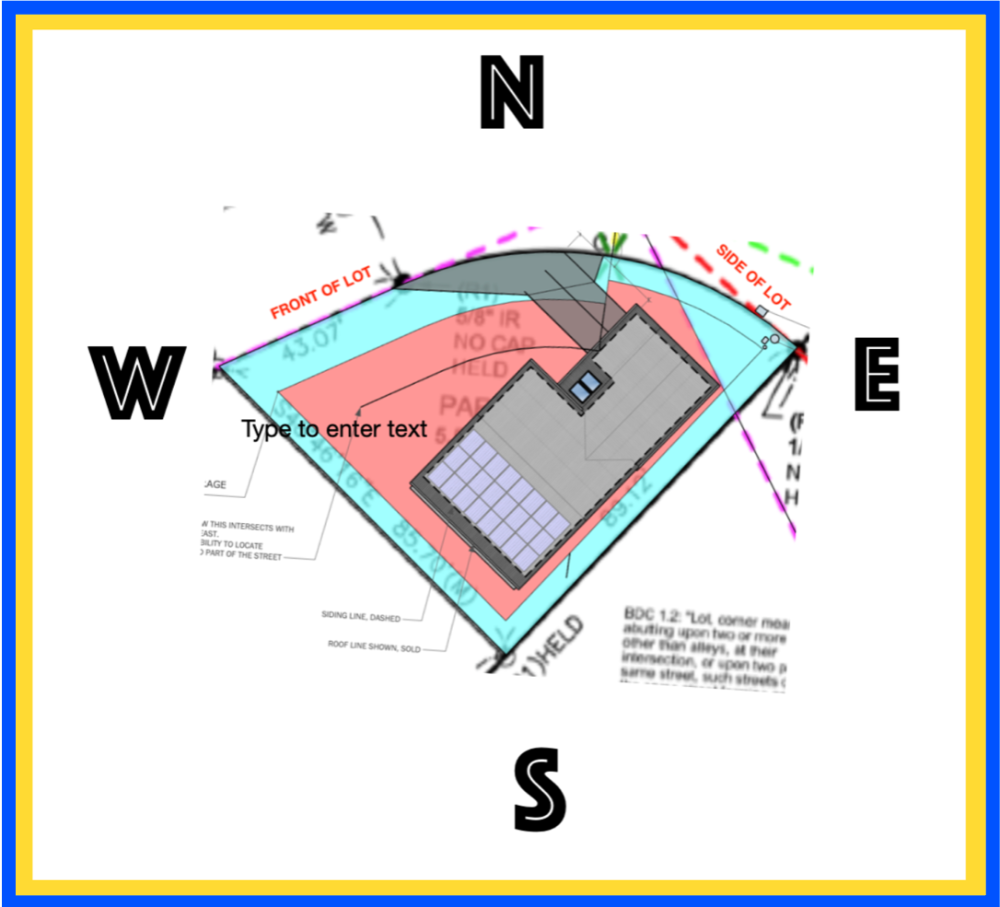

1. Orientation to the Sun

Our house will be oriented on our lot to maximize winter solar heat gain from the south. As you can see from the figure, we were able to find property where we could orient the glass wall mostly to the south. We are several degrees west of south and do have some shading from the neighbors’ trees, but our orientation will allow us to receive 77% of the total sun available to our address over a year’s time. That SSW side is mostly glass windows engineered to allow for optimal heat gain for space heating in the winter.

2. Super Insulation

Our house will have 9 inches of rigid foam insulation under the (concrete slab) floor. The walls will be 11 inches thick: the inner 8 inches dense-packed fiberglass, the outer 3 inches outside the sheeting Roxul insulation (a spun basalt material). We top this off with 25 inches of loose-packed fiberglass insulation in the attic. This will give us a super-insulated envelope: R-45 under the floor, R-47 walls and R-72 attic. Even our windows will average R-9!

3. Air-Tight Construction

A certified Passive House is about as leak-proof as a home can be. Leakage or air infiltration is measured in Air Changes/Hour (ACH) at 50 pascals of pressure. 1 ACH means that, under pressure, all the air in the house will leak out one time in an hour. 2 ACH means all the inside air will leak out twice, etc. Well-built conventional homes leak at a rate of 3-4 Air Changes/Hour. For PH certification, ours must test at .6 ACH or less. In Passive House #1, we achieved a .51 ACH score with “Henry’s Blueskin,” a sticky-backed, self sealing, poly wrap applied to the walls and ceiling. Passive #2 will be sealed with a newly patented process called AeroBarrier (northwestaerobarrier.com). When the house is fully closed up, a non-toxic, low VOC, water-based sealer will be released inside the shell of the house under pressure. This sealer seeks out and fills all leaks and has achieved scores of around .2 ACH. In addition, we will minimize the number of holes required in the envelope for wiring and venting. For instance, the clothes dryer will be vent-less and the hood over the stove won’t vent to the outside but filter and re-circulate air to the inside.

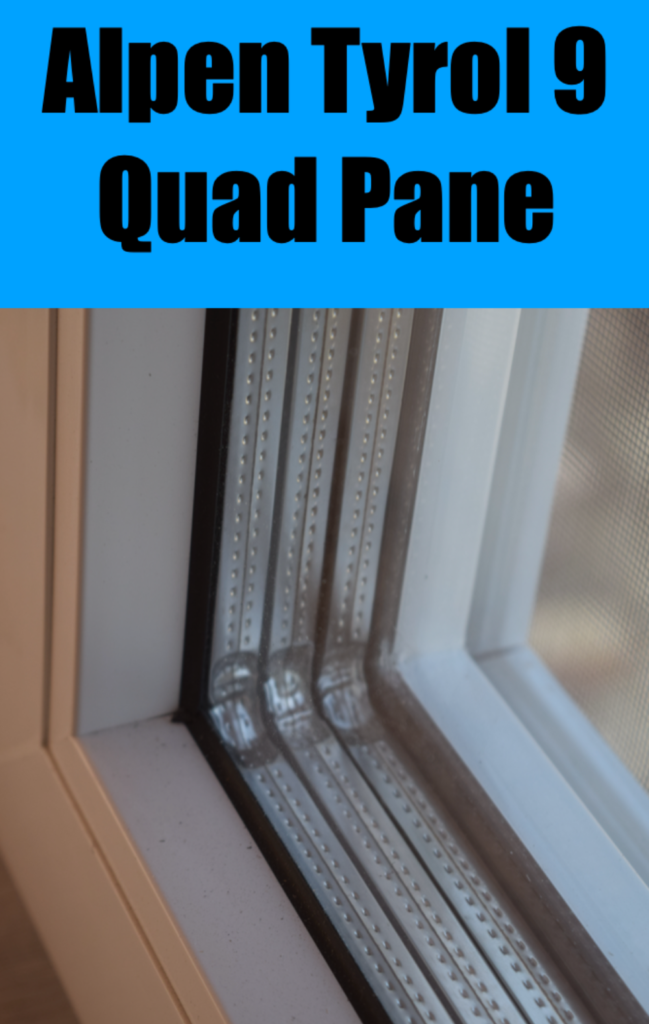

4. High Performance Windows

Our windows will be quad pane Tyrol 9 PH+ High-Gain windows manufactured by Alpen Windows in Louisville, Colorado. Constructed with low-e suspended film and krypton gas between the four panes, they are engineered to keep harmful ultra-violet light and infrared heat outside the house and hold heat/coolness inside. Insulating values of windows are measured by U-factors (lower is better) and R-factors (higher is better). The heat gain coefficient (SHGC) measures how much radiant heat the window will transmit from sunlight to heat the house in winter. Ratings of our Alpen 9 PH + windows: U-value = .11; R-value = 9 3; SHGC = .35

These are amazing. For instance, a 2×4 stud wall insulated with fiberglass batting achieves R-14. At R-9, our windows are almost as well insulated as a wall!

5. 24/7 Energy Recovery Ventilation (ERV)

We toured hundreds of people through Passive House #1 and one of the most asked questions was how we could live in a house so air-tight. Many had heard the horror stories of 30 years ago when the earliest experiments with super-air-tightness turned homes into moldy slime balls! Our Zehnder Energy Recovery Ventilator (www.zehnderamerica.com) will be the lungs of our house, breathing 24/7 to completely replace stale indoor air with fresh outdoor air every 3 hours. As the two airstreams pass, 90% of the heat and humidity from the out-going air is “recovered” and exchanged to the incoming air, conserving energy while refreshing the space. An airtight Passive House seals in all the heat and humidity from doing loads of laundry in the ventless clothes dryer, cooking pasta under the circulating hood, getting sun through insulated windows and hot-steamy grandchildren doing Rubber Ducky maneuvers in the Tubby! In all things Passive, Zehnder rules!

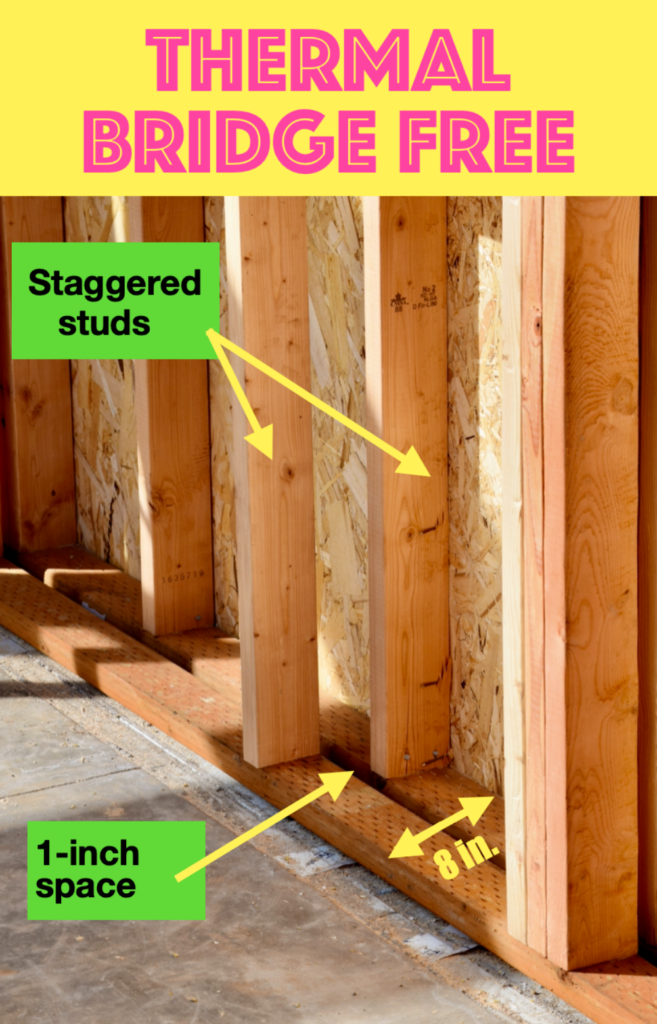

6. Thermal Bridging-Free

Thermal bridging happens when a poorly insulated material allows an easy pathway for heat to flow across a thermal barrier. In a traditional home, wall studs have batt insulation between them, but the sheet rock wall is attached directly to a stud on the inside of the house with plywood sheeting nailed to the same stud on the outside. Wood and sheetrock have a far lower R-value than fiberglass, allowing heat and coolness to easily “bridge” the wall through the studs. This compromises the ability of the house to keep cooler in summer and warmer in winter. Our wall structure prevents bridging with two 2×4 stud walls, side-by-side, separated by an inch with studs staggered so when the cavity is full of fiberglass all wall components are separated by insulation. To block bridging where walls meet the floor, there will be a continuous layer of rigid insulation beneath the floor and up the outside of the concrete foundation connected to the insulation in the wall. Finally, while most windows are notorious thermal bridges through metal framing or steel reinforcing rods in vinyl, our Alpen window frames are metal-free uPVC, reinforced with fiberglass for strength.

I could apologize for the length and technical content of this blog, but get this: If you are still with me, you are surely the first person on your block to have any knowledge of what a certified Passive House is and why this kind of construction may mean the difference between our kind thriving into the next century or sliding further into the Anthropocene or what E.O. Wilson has called the Plasticene, the Obscene or the Unforgivablecrimescene. For the PH certifiers, these principles are just principles. They are voluntary. But here’s the bottom line: To get certified our house must perform! The proof is in the passive pudding!

1. Energy for heating must not exceed 15 kWh per sq. meter (floor space) annually.

2. Total energy use must not exceed 60 kWh/sq. meter or 5,760 kWh per year.

3. For air tightness, the envelope must test at a max of .6 ACH leakage at 50 Pascals.

4. For comfort, not more than 10% of the hours in a given year can exceed 77 degrees (F).

Finally, then, could this kind of building performance mean the difference between the American Dream being a desecration or a sacrament for Earth? Let’s keep the conversation going. We know the average U.S. household uses the equivalent of 10,715 kWh each year. When we meet the PH standard of less than 5,760 kWh, we can add what it takes to charge our EV and still come out below average! I hope you can see this isn’t just about us and the insignificant amount of bend toward justice and healing ours will add to the “moral arc of the universe!” With building floor area around the globe set to double by 2060, we need certification standards, codes and the political will to put into practice what we value for the habitations of everyone and everything.

The words of Sallie McFague are right on:

We do not own the house; we do not even rent it. It is loaned to us for our lifetime, with the proviso that we obey the above rules so the house can feed, shelter, nurture, and delight those who move in after us. These rules are not laws we can circumvent or disobey; they’re the conditions of our harmonious coexistence, and they are constitutive of our happiness.

Next time we’ll start with excavation and laying the foundation of our build. In the meantime, I love the idea of building for harmonious co-existence, for happiness and delight!

Thanks for all the technical info, John. I loved reading about all the new advances in energy efficiency in the building industry and the ways your new house will differ from your first passive house. Loved the picture of Jackson as well! Keep you posts coming, please.

Thanks for being an inspiration as an early adaptor and advocate.

Love the update for your new home.

My home is a 1949 building in Springfield, OR. I’ve been monitoring my energy use since putting up a 4.02 KWH PV Array in January 2019.

My total electric use in 2021 was:

PV Generation 5594.28 KWH

PV to SUB (local utility) 3689 KWH.

SUB purchased – 3216 KWH

**Means I generated 473 KWH more than I used for the year.

I live alone, use a wall mounted Heat Pump , heat with south facing Solarium, drive a 2013 Leaf, house is south facing with living/dining/kitchen on south side, attic has great insulation and is sealed from in-house air, flooring is adequately insulated, walls are uninsulated because sheet rock is 1/4″ and was installed with nails (can’t pay anyone insulate them).

Keep this information coming,

Rouanna